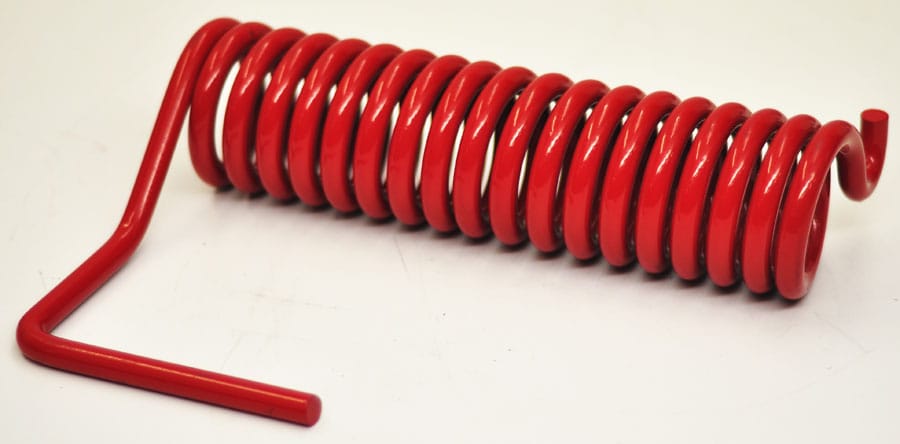

Torsion Springs

MANUFACTURED EXACTLY HOW YOU NEED THEM

Torsion springs are helical coil springs that are used to exert a torque or rotational force and are subjected to bending stresses. They are usually mounted over a shaft or mandrel and are supported at the ends.

Torsion springs must always wind up as the torque is increased, never unwind from the free position. The direction of coiling will be predicated by the direction that the force is applied. Note that diameter of a Torsion spring will always reduce as the torque is applied. This reduction in diameter must be considered to maintain clearance between the support shaft and the Inside Diameter of the spring.

Ideally a Torsion Spring should have a slight space between the coils to allow for the body lengthening that occurs as the torque is applied.

Torsion spring ends come in various end configurations depending on the designs of the mounting. The most common and simplest torsion spring ends are straight tails. The angle between the two tails varies depending on the torque or rotational force required and the application. Other special end configurations are used based on the uniqueness of each mounting system. RMW Industries Inc. has custom designed and manufactured torsion springs with different type of ends configurations. We design torsion springs with the correct rotational force and stresses to ensure that your torsion springs will do the job they are supposed to with long fatigue life.

Trust RMW Industries Inc. to manufacture quality torsion springs.

Torsion Springs Manufactured to Your Specifications Request Quote

- To your specifications or approved drawings

- Custom design and build torsion springs to meet your needs

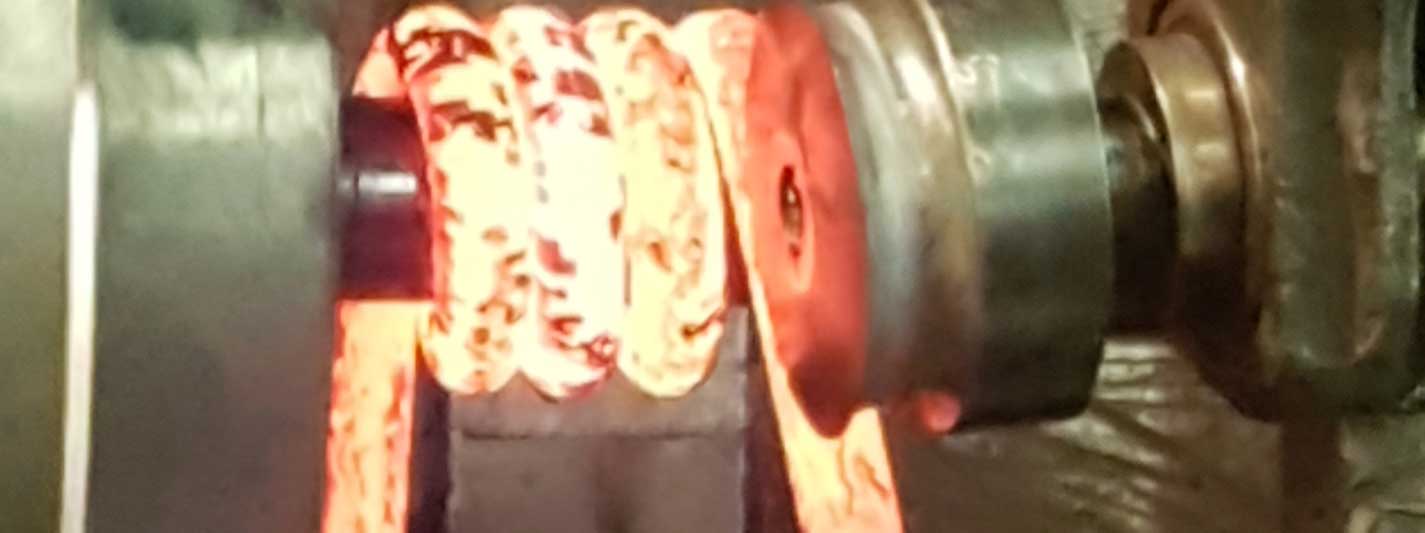

In-House Coil Manufacturing Process

- Complete in-house processes take your torsion springs from raw material to finished product ready for their designed purpose, all with an expert team dedicated to quality

unique specifications Request quote